The Rowan University Air Engine

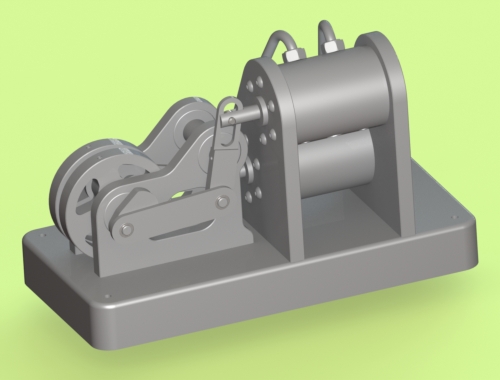

We have built a simple prototype engine for you to use as a basis for your design, if needed. Most of the engine was built using a manual milling machine and lathe, although some of the framework was fabricated on a CNC machining center. All parts can be made on manual machines, if you don't mind eliminating some of the fancy curves and 'lightweighting' holes in the framework and flywheels. We have included a full set of SolidWorks parts, assemblies and shop drawings (download below) for your convenience. A rendering of the Rowan Air Engine is shown below. Hover the cursor over the purple buttons to see the relevant assembly highlighted in the figure.

Materials

The base and framework for the engine are made from aluminum, as are all the links. The flywheels are made of brass, for added rotational inertia. The pistons are made from Delrin, which is the brand name for acetal plastic. There are quite a few ball bearings and bronze bushings in the assembly, and they can all be found at McMaster-Carr.

Parts List

The link below gives an Excel spreadsheet with the parts, assemblies and materials needed to build the air engine. Each subassembly has its own tab, and the color-coding is as follows:

- Blue - assembly

- Green - manufactured part

- Pink - purchased part

SolidWorks Files

The link below gives the zipped SolidWorks parts, assemblies and shop drawings for the Rowan air engine. Please keep the directory structure intact, otherwise SolidWorks won't be able to find the parts in each assembly. I have not supplied all of the tolerancing information on the drawings, mainly because of a lack of time. If you are planning to 'send out' all of the parts to a local machine shop, you'll need to add your own tolerancing information, or discuss it with the machinist. Please let me know if I've left out any important information on the drawings!

This file is rather large (8.3MB) so be prepared for a lengthy download.

RowanAirEngine.zip