Hybrid Control Strategy

There are two major goals that automakers wish to achieve when designing a hybrid-electric drivetrain:

- Load leveling - by combining the power from the IC engine and electric motor when loads are high, we can get away with using a smaller IC engine. A smaller IC engine reduces weight and has lower frictional losses in comparison with a larger engine. In addition, IC engines are typically more thermodynamically efficient as they operate closer to their own peak load capability and are very inefficient at light loads. Since vehicles spend a significant amount of time at low loads (i.e. cruising), a smaller IC engine will spend more time closer to its peak load than a larger engine, thus achieving higher average efficiency. Since the smaller engine may not have the power to meet high load situations (hard acceleration, uphill) the electric motor can be used to provide supplemental power. During light loading (cruising, driving downhill, or coasting) one or both engines can be turned off. Of course, we must have a charged battery pack in order to be able to use both motors simultaneously, which brings us to...

- Regenerative braking - an IC engine has no means of storing energy when the car is driving downhill or braking. If we use the electric motor 'backwards' as a generator, we can store the energy from braking in a battery pack. This energy can be used later during heavy parts of the load cycle (fast acceleration, driving uphill).

There are several different types of hybrid-electric vehicles that manufacturers have developed. We will describe the four major types here.

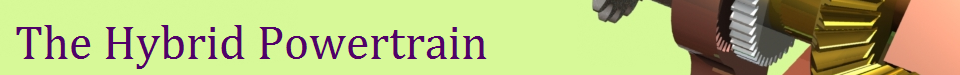

The Series Hybrid

The series hybrid has the IC engine, generator, and motor/generator connected in series, as the name indicates. In this system, the IC engine is used to drive the generator, which can charge the battery pack or drive the electric motor at the wheels.

Pros

- The IC engine is not connected directly to the wheels, so its speed is not dependent upon the speed of the vehicle. Thus, it can run at its most efficient speed at all times, and can be turned off entirely under light loads when the battery pack is charged. This EV-only mode is especially advantageous during stop-and-go city driving.

- The control strategy for the series hybrid is quite simple since the generator and IC engine are decoupled from the wheels.

- This system permits regenerative braking, since the motor/generator can also be used to charge the battery pack.

- This system also permits opportunity charging, where the IC engine drives the generator and charges the battery pack. Since it is decoupled from the wheels, this can even be accomplished when the vehicle is at rest.

Cons

- Since all parts of the system run in series, the conversion losses multiply. There are several conversion losses in the system, including

- IC engine to generator (mechanical to AC power)

- Generator to battery charging (AC power to DC power)

- Generator to motor/generator (AC power to DC power)

- Battery discharging to drive the motor/generator

Since all of these losses operate simultaneously, the overall efficiency of the series hybrid is quite low, and can even be less than the IC engine operating alone! For example, lets assume the engine can generate mechanical power at its peak efficiency point of around 35%. Lets also assume that the conversion of mechanical power to AC electricity, the conversion to DC power, the charging or a pack with this DC power, the discharging of a pack, the conversion of this DC power back to AC, and finally the conversion of AC power to mechanical power each have an efficiency of 95%. Multiply those six 95% efficiencies together with the engine efficiency yields an overall of around 26%. Depending on the drive cycle, that may not be more efficient than an engine simply powering the wheels alone and being forced to operate at somewhere other than its peak efficiency point. For this reason, series hybrids are rarely seen in practice, except in very large applications such as diesel electric trains, ships and the like.

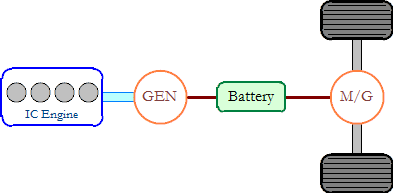

The Parallel Hybrid

In the parallel hybrid the IC engine and motor/generator are connected to the same shaft. This shaft drives the wheels through a transmission. In some parallel hybrids, the motor/generator is located after the transmission and may have its own gear reduction before connecting to the driveline. Regardless of exact layout, the IC engine and motor/generator are both directly coupled to the wheels and their speeds are mechanically linked to each other as well as to wheel speed. During braking and downhills, the wheels can drive the generator to charge the battery pack. Also, the IC engine can be “throttled up” to drive the generator and charge the battery pack during light loads. In this situation, the generator acts as a “brake” on the engine in order to keep the wheels at the desired speed.

Pros

- Since the IC engine and motor/generator are connected directly to the wheels, the energy conversion losses are minimized.

- This scheme is simple to implement in an existing vehicle, since it only requires the connection of the motor/generator to the existing output shaft of the IC engine.

- Regenerative braking is achievable.

Cons

- Because of the direct connection between the IC engine and the wheels, the engine cannot run at its most efficient speed all of the time. It is impossible to decouple the IC engine from the wheels (and shut it off) without the addition of a clutch.

- EV-only mode is not possible.

- Opportunity charging is also impossible. The IC engine can be used to help charge the battery pack, but it must follow the wheel speed while doing so.

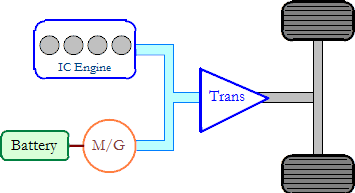

The Power Split Hybrid

The power split hybrid, shown in the figure above, overcomes many of the difficulties faced by the parallel and series hybrids, at the cost of a complicated control scheme. It uses a planetary gearset (shown as PG in the figure above) to combine power input from the motor generator (MG1) and the IC engine. A second motor/generator (MG2) is connected directly to the wheels. The purpose of the planetary gearset is to combine the speeds of the IC engine and MG1 to produce the desired wheel speed. Because of this, the IC engine can run at its most efficient speed, and MG1 is used to maintain the correct wheel speed. Regenerative braking is accomplished through MG2.

Pros

- EV-only mode is easily achieved by using MG1 and MG2 to control wheel speed.

- Opportunity charging is also easy to accomplish.

- Same with regenerative braking.

- Since each motor is mechanically connected to the wheels via the planetary gearset, conversion losses are minimized.

Cons

- The control scheme is a little complicated.

- This system is more challenging (and expensive) to implement than the parallel or series hybrids, at least initially. The gains in efficiency, however, offset the additional cost.

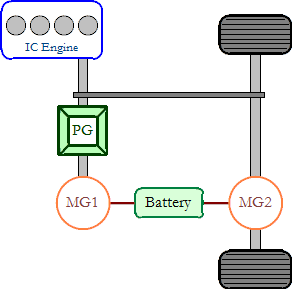

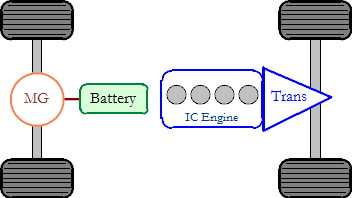

Through the Road Hybrid

The system shown in the figure above is known as a through-the-road hybrid. One set of wheels is directly coupled to a motor/generator and the other set to the IC engine. During light loads, the IC engine can be run at its maximum power with the motor/generator acting as a 'brake' as it charges the battery pack. During high loads, the motor/generator and IC engine can be used simultaneously, at least until the battery pack is discharged. This capability, and the added traction of putting power down through all four wheels, has let to its adoption in racing and high-performance vehicles, where short bursts of very rapid acceleration are useful. The through-the-road hybrid is sometimes considered a type of parallel hybrid since both the engine and motor power the wheels together. However, the physical link between the two is through-the-road rather than, say, geared together driving the same axle.

Pros

- EV-only mode is possible using the clutch in the transmission.

- Regenerative braking is also possible.

- Opportunity charging is sometimes possible (as described above) but only when the vehicle is moving at sufficient speed to turn the motor/generator.

Cons

- Opportunity charging cannot be done with the vehicle at rest.

- Like a parallel hybrid, the engine in a through the road can not be run at its most efficient point since it is still mechanically linked to road speed.

- Packaging can be quite difficult and end up eating significantly into passenger compartment space since the drivetrain is spread out between both axles.